Every test technician needs to know which piece of electrical test equipment to use for the job at hand, as well as understand the limitations of the test equipment. Electrical testing is performed by applying a current or voltage to a circuit and comparing the measurement you get to an expected result. The test equipment electrical specialists use verify the math behind the circuit and every piece of testing equipment is designed for a specific task. Electrical test equipment is a source of deadly electrical energy, and professionals must follow all safety precautions and observe all safety warnings to prevent contact with the energised parts not only of the test equipment itself, but also the related circuits. Here's some of the most commonly used types test equipment in industrial, commercial and household applications.

Multimeter

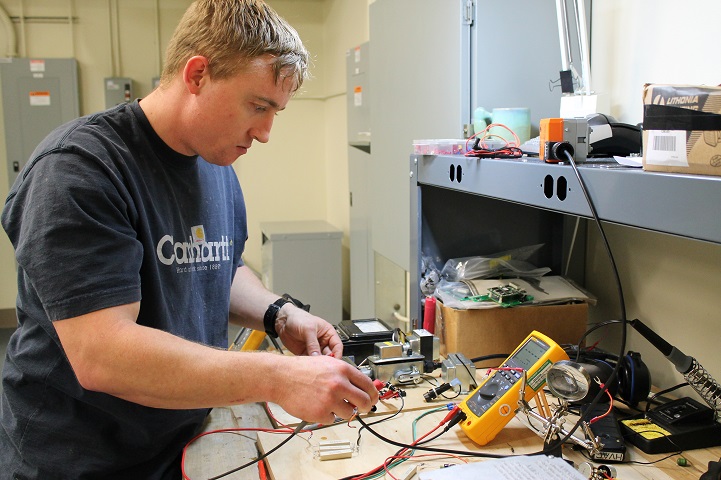

Multimeters are also known as Volt-Ohm meters (VOM), and they're basically a handheld device that can perform a variety of measurement functions, such as current, voltage, frequency and resistance. They're mainly used to troubleshoot electrical issues in a variety of industrial and household devices, including motor controls, electronic equipment, power supplies, domestic appliances and wiring systems. Digital models are the most common type used today, but analog models are still preferable in some situations, such as when monitoring sensitive measurements or a rapidly changing value, such as testing for CT polarity.

Megohmetter

These are also referred to as meggers, and they're a special type of ohmmeter used to measure electrical resistance in insulators. The resistance values of these meteres can range from just several megohms up to several teraohms. Meggers produce high voltages with the help of manually operated generators or battery powered internal circuitry with outputs ranging from 250-15.000V. This type of testing equipment is one of the most frequently used, and they can measure the insulation of many different types of apparatus, such as switchgear, transformers, circuit breakers and cables.

Low-Resistance Ohmmeter

Also known as DLRO, low-resistance meters are used for making accurate resistance measurements under 1 ohm. These meters produce low voltage DC currents with the help of battery power with outputs of up to 100 amps. The measurements are performed with 4 terminals known as Kelvin contacts. Two of them carry the current from the meter, while the other two enable the meter to measure voltage across the resistor. With low-resistance ohmmeters, any voltage drop that's a result of the resistance of the first pair of terminals and their contact resistances is ignored by the tester. These pieces of test equipment electrical professionals use for a wide range of apparatus, including switch contacts, circuit breakers, cables, busways, generators, transformers, fuses and motor windings.

Winding Resistance Testers

Winding resistance measurements are important diagnostic tools for assessing potential damage to motor windings and transformers. Winding resistance in transformers changes as a result to shorted turns, deteriorating contacts and loose connections in tap changers. You get these measurements by passing a predetermined DC current through the winding that's being tested and measuring the voltage drop across all terminals. Modern testers for this purpose utilise a Kelvin bridge to get results. You can think of winding resistance testers as a large low-resistance ohmmeter. Winding resistance testers feature 2 voltage leads, 2 current leads and 1 ground lead. The typical current range of these testers is 1-50A. Higher currents reduce test times on high current secondary windings.

Ground Resistance Testers

These testers provide measurements by injecting current into the earth between a remote probe and test electrode and measuring the voltage drop caused by the ground to a designated point, then using Ohm's law to calculate the resistance of the ground. These testers come in a range of styles, with the most common being 4 terminal units for relativity testing and 3 terminal units for fall-of-potential testing. They feature copper rods to make contact with the earth, as well as spools of small stranded wire to cover longer distance measurements. There are also clamp-on testers that measure ground grid and rod resistance without using any auxiliary ground rods. These models provide precise readings without disconnecting the ground system that's being tested.

Thermal Image Testers

Thermal imagers detect invisible infrared radiation and display that data into a coloured image on a digital screen. These testers are usually used for inspecting the integrity of electrical systems, as they can be performed quickly without contact on equipment that's in use. Comparing the thermal signatures of normally operating equipment to the one being tested for abnormal conditions is a great way to troubleshoot. Even if the abnormal thermal image isn't fully understood, it can be used to figure out if further testing is required. These testers are classified based on resolution and accuracy. High-end models feature high resolution images and temperature accuracy down to a 0.1 of a degree or even less.

Thank you for sharing the valuable content.

ReplyDeleteBattery testing equipment determine the condition of lead-acid and nickel-cadmium cells ,String, Battery capacity, Electrical power. Robust,repeatable instruments, Measures float and ripple currents.